Bridging the Gap: Digital Twin Integration and Evaluation in Robotic Multi-Axis Additive Manufacturing

This repository contains files for the paper titled "Bridging the Gap: Digital Twin Integration and Evaluation in Robotic Multi-Axis Additive Manufacturing," with Tomáš Jochman as the main author. To get the source codes and project, please contact one of the authors tomas.jochman@cvut.cz or pavel.burget@cvut.cz.

Citation: T. Jochman et al., “Bridging the gap: Digital twin integration and evaluation in robotic multi-axis additive manufacturing,” in 2024 22nd IEEE International Conference on Industrial Informatics (INDIN). Beijing, China: IEEE, 2024.

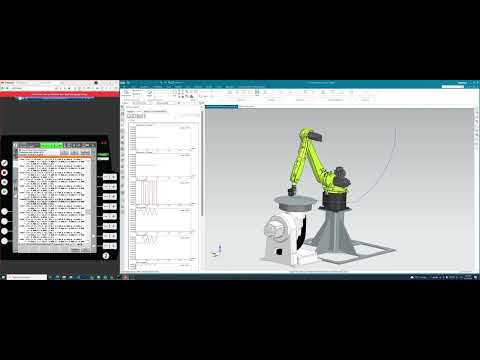

This study explores integrating digital twin technology with robotic multi-axis additive manufacturing to improve manufacturing precision and efficiency. A laser tracker calibrates the machine workspace and tools, incorporating an industrial robot with a filament extruder head and a rotary-tilt positioner. The digital twin captures the details of the manufacturing process and automates code generation for robotic operations. The method's effectiveness is shown through the production of two complex parts, assessing their dimensional accuracy to evaluate the technology's limits and potential. The results show substantial improvements in aligning virtual models with physical objects, demonstrating the digital twin's ability to reduce common deviations in traditional manufacturing.

- Digital Twin Integration: The study successfully integrates a digital twin (DT) with robotic multi-axis additive manufacturing, enhancing manufacturing precision and efficiency by bridging virtual planning with physical execution.

- Laser Tracker Utilization: A laser tracker is employed to calibrate the machine workspace and tools, introducing a system that combines an industrial robot with a filament extruder head and a rotary-tilt positioner.

- Automated Code Generation: The digital twin automates the generation of robotic operation codes, encapsulating the geometric and operational intricacies of the manufacturing process.

- Demonstration through Complex Parts: The methodology's application is demonstrated through the production of two complex parts, assessing their dimensional fidelity to evaluate the precision limits of digital twin technology.